Creeker

Wildcat

Registered: 01/08/09

Posts: 53

|

| | 02/16/09 at 07:21 AM | Reply with quote | #13 |

|

Quote: For them to operate the Master Caster, the moulds have to have a rounded lube groove.

I respectfully disagree. Because of it’s design the Master Caster will dislodge bullets with square lube grooves. I have three moulds set up for a Master Caster, the L429421 and RCBS 44-250-K, and Ballisti Cast 1103. All will fall from the mould on the first hammer if not the second. You may be referring to the automated machines as opposed to the manual ones.

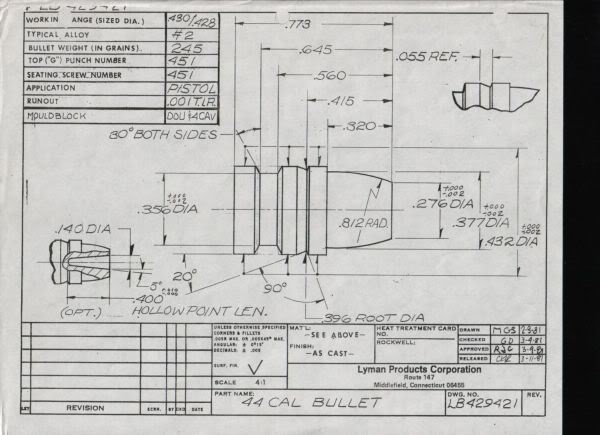

As for the square vs round lube groove, it’s something I feel will never be settled. I’ve seen both that shoot equally well. The one we produced was a Lyman 429421. As you can see by the blueprint below my two 4 cavity Lyman moulds use lube grooves which aren’t 90 degree. In my own testing I find this in no way places it at a disadvantage to the square lube groove bullets.

This bullet was shot at one of the Linebaugh shoots long ago. The bullet was better at long range than the LBT’s and others according to reports. John Taffin, Brian Pearce, Dave Scovill, and ole friend Dave Clements have all used and find it takes the back seat to none including the RCBS 44-250-K and RCBS 44-245-SWC.

As I said the round vs square groove debate goes on. God Bless.

Lynn & Barbara

Dry Creek Bullet Works

__________________

God Bless,

Creeker

Dry Creek Bullet Works

Dry Creek Firewood |

| Loading... | |